A Closer Look at Grain Size, Surface Area, and CDR Performance in Our Greenhouse Experiment

What Two Years of Data Reveal About EW Performance

Over the past two years we have run the largest controlled greenhouse experiment for enhanced weathering that we know of. With hundreds of pots, multiple soils, and a wide range of rock types, the goal was straightforward. We wanted to understand how rocks behave in real soil environments and which combinations deliver meaningful carbon removal.

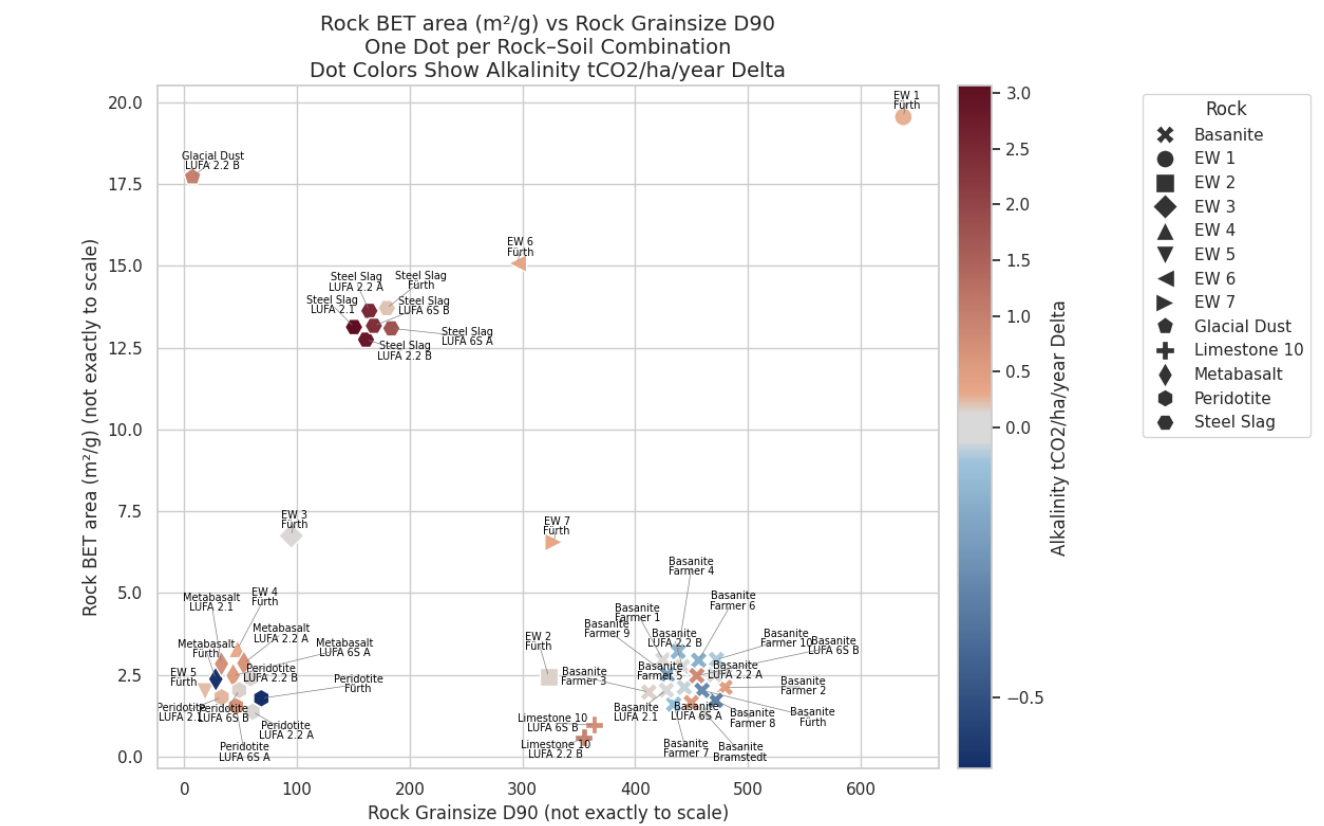

One of the most useful outputs is a multidimensional graph that brings several variables together. The x-axis shows each feedstock’s D90 grain size in microns. The y-axis shows the surface area in square meters per gram. The color of each marker represents the measured CDR performance in tons of CO₂ removed per hectare per year. To make trends easier to see, the markers are slightly spaced out, so the axes are not perfectly to scale.

1. Grain Size and Surface Area Do Not Necessarily Correlate

Grinding a feedstock to below 100 microns does not guarantee a large reactive surface area. Depending on the mineralogy and the grinding method, particles may remain rounded, edgy, or plate-like. These microstructures create large differences in how much reaction surface becomes available to weather.

This has practical implications. Simply grinding “finer” is not enough to ensure strong CDR performance.

2. Larger Surface Area Helps, But Chemistry Still Wins

A larger surface area usually leads to faster weathering. Many of the high-surface-area materials produced strong CDR signals because the available reaction surface is significantly larger.

But this is not the whole story. Several lower-surface-area feedstocks still delivered meaningful CDR performance. In these cases the key driver was chemistry, not particle geometry. This means EW design cannot rely on surface area alone as a predictor.

3. Basanite and Basalt Show the Widest Variation

Among all materials tested, basanite and basalt produced the broadest spread of CDR results. Their performance depended heavily on the soil they were applied to. Some soils supported strong weathering while others suppressed it.

This reinforces a core idea. Enhanced weathering is not “choose a rock and spread it everywhere.” It is about matching the right rock to the right soil.

4. Steel Slag Was the Most Consistent Performer

Steel slag produced strong CDR performance across all soils in the experiment. Its chemistry makes it highly reactive, and the weathering signal remained reliable even in soils that were less favorable for natural silicates.

This consistency makes it a useful near-term option while more natural feedstocks scale and diversify.

5. Fürth Soil Was the Weakest Performer

Our own Fürth soil produced the lowest CDR rates of the entire lineup. This is a valuable insight. Some soils simply do not offer the chemical conditions needed for fast weathering, and identifying them early prevents wasted effort.

Why These Results Matter

Taken together, these insights help us understand where EW can succeed quickly, where it requires careful matching, and where it will struggle no matter what. The experiment gives us a more precise scientific basis for selecting feedstocks, choosing soil environments, and scaling enhanced weathering with fewer blind spots.

For the full technical breakdown and the complete dataset, visit our blog:

https://www.carbon-drawdown.de/blog/2025-1-29-what-we-learned-from-the-worlds-largest-greenhouse-experiment