How to make biochar at different scales, large and small (ft. Syncraft & Cotierra)

The problems facing our climate won’t be solved with a single blueprint. Instead, solutions must be tailored to geography, infrastructure, and real-world constraints. Biochar is a good example of how the same climate tool can require very different system architectures to work at scale.

Two of our portfolio companies, Cotierra and SYNCRAFT, show why.

SYNCRAFT: Infrastructure-Class Carbon Removal

SYNCRAFT builds large, centralized biochar plants called Reversepowerplants – what you might call infrastructure-class systems.

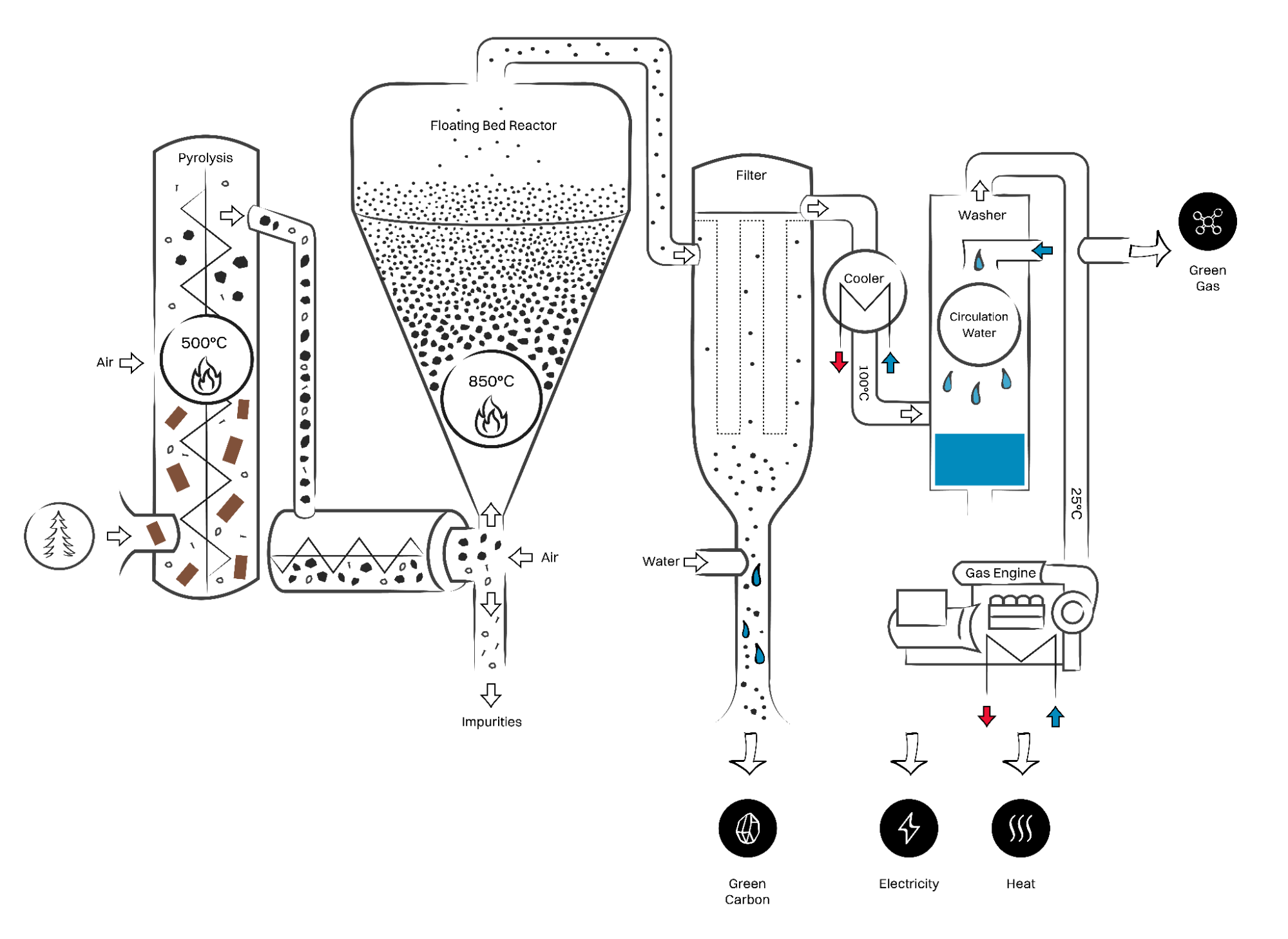

Each Reversepowerplant operates in modular units of roughly 500 kW to 2 MW, with development timelines of one to three years. These systems are designed to extract nearly everything from biomass, including:

Electricity

Heat

Green gas

High-purity biochar (called green carbon)

A visual illustration of a Reversepowerplant schematic

More than 95% of the biomass is utilized, pushing close to the theoretical maximum for energy efficiency. This is not experimental technology. SYNCRAFT systems have already delivered hundreds of thousands of cumulative operating hours across installations all over the world – an important threshold, because this level of robustness is what makes infrastructure financing possible in the first place.

The model is especially powerful in developed regions, where district heating networks exist, electricity can be fed into the grid, and roads and logistics support moving biomass to the plant and biochar from it. The result is a highly optimized system that turns regional wood into renewable energy and long-lived green carbon products, including biochar pure enough for industrial uses such as steelmaking.

This is biochar as backbone infrastructure: capital-intensive, but exceptionally efficient.

SYNCRAFT scales by concentration. By aggregating biomass, energy use, and capital into fewer, highly optimized systems, it maximizes efficiency per site and unlocks financing models typically reserved for energy and industrial infrastructure. This is how biochar becomes something planners, utilities, and financiers can actually build around.

(See our full SYNCRAFT spotlight for technical depth and milestones)

A complete SYNCRAFT Reversepowerplant

Cotierra: Carbon Removal Where Infrastructure Doesn’t Exist

Cotierra reactor rendering

Cotierra is designed for the opposite context: regions where agricultural biomass is widespread, but infrastructure is limited. This is the norm across much of the Global South, where logistics, missing energy offtake, and capital intensity make centralized biochar systems difficult to deploy at scale.

Instead of moving biomass to a plant, Cotierra moves the plant to the biomass.

Their solution uses small, mobile pyrolysis units that are driven directly onto farms. Agricultural residues – such as pruning waste or low-density crop residues – that would otherwise be open-burned or left to decompose (both options release the already fixed carbon back into the atmosphere) are converted into biochar on site.

Key differences by design:

No need for road-heavy transport

No reliance on grid access

No requirement to monetize heat or electricity

Yes, some energy is not captured. But without Cotierra, that same biomass would typically be burned anyway, sending all of its carbon straight back into the atmosphere. By minimizing transport and operating directly with farmers, Cotierra opens up entire biomass streams that centralized plants simply cannot reach, especially in remote, less accessible regions.

Cotierra reactor in action

The biochar stays on the farm, where it is optimized for soil improvement, water retention, and resilience, rather than industrial substitution markets. This locks the carbon away for centuries while directly benefiting local agriculture.

Cotierra scales by distribution. By lowering logistical, infrastructural and capital requirements, it prioritizes reach over optimization, capturing carbon where no centralized system would ever be built. The strength of this model is not peak efficiency per unit, but the ability to operate across thousands of small, otherwise unreachable sites.

This is carbon removal that works where infrastructure is weak, but climate vulnerability is high.

(You can read our detailed Cotierra spotlight here: https://www.carbon-drawdown.de/blog/2026-1-24-portfolio-spotlight-cotierra-turning-agricultural-waste-into-climate-resilience

Why This Comparison Matters

At Carbon Drawdown Initiative, we don’t seek one winning architecture. We look for systems that work in context. SYNCRAFT excels where infrastructure exists and energy can be fully utilized. While Cotierra excels where transport, grids, and centralization are barriers, not advantages.

The climate challenge is not choosing the “best” architecture. It’s expanding the set of places where carbon removal is possible at all. Some regions need concentration, and others need coverage.

Together, they show what real climate progress looks like: not a single silver bullet, but complementary tools that expand the total solution space.

If we want carbon removal at a climate-relevant scale, we’ll need both.